Your Trusted Manufacturer of PVC Foam Board, WPC Foam Board, Trim & Moulding – Boardway China

- 📧sale@boardwaybuilding.com💬86 138 2826 6785

Support

We are committed to providing our customers with valuable products that meet their expectations and are regularly reviewed to ensure a commitment to continuous improvement. At Boardway, our dedication to quality, innovation, and environmental responsibility sets us apart.

RESEARCH & DEVELOPMENT

Boardway is dedicated to the ongoing research and development of plastic solutions. Our goal is to find innovative solutions, enhance product performance, and provide customers with superior and tailored products.

While plastic products may seem simple, the entire process, from raw material procurement to final product performance testing, requires precise formula adjustments, equipment debugging, and rigorous testing.

With over 15 years of plastic manufacturing experience, Boardway guarantees consistent product quality and can customize plastic sheets to meet specific customer needs. Additionally, any unqualified products are recycled to minimize material waste.

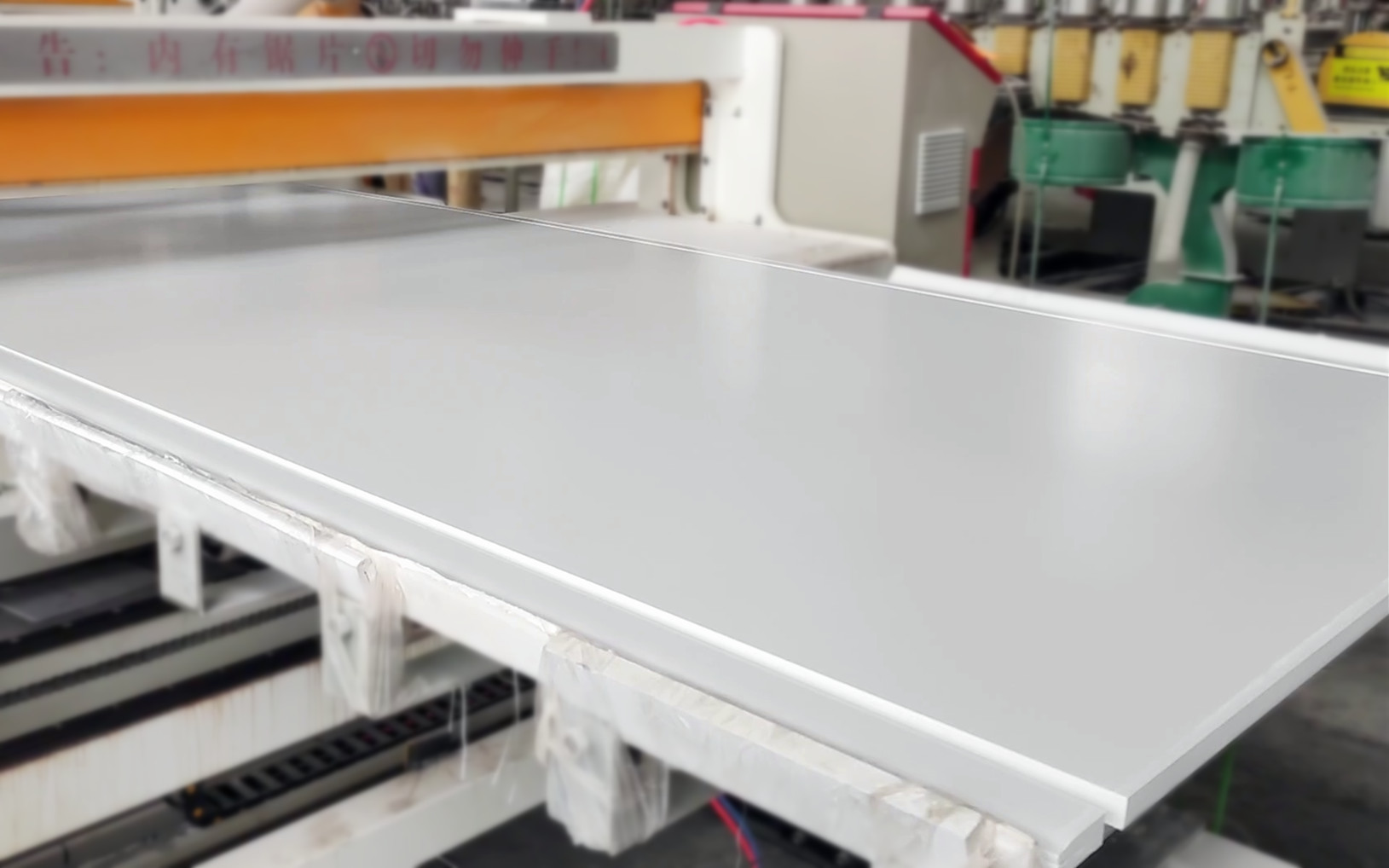

MANUFACTURE & PROCESSING

Established in 2006, Boardway has over 15 years of experience in plastic sheets and profiles manufacturing. We specialize in the production, wholesale, and processing of a wide range of plastic products.

Our product offerings include expanded PVC foam board, WPC foam board, PVC concrete formwork, PVC profile extrusion, rigid PVC sheet, solid polypropylene sheet and lightweight hollow polypropylene sheet.

With factories located in Zhejiang, Guangdong, and Jiangsu Province, covering a total area of 720,000 square feet, we are dedicated to providing safe and high-quality products. Our plastic sheets are customized to meet REACH, RoHS, and SVHS safety standards, and we also offer processing support, as well as OEM and ODM services.

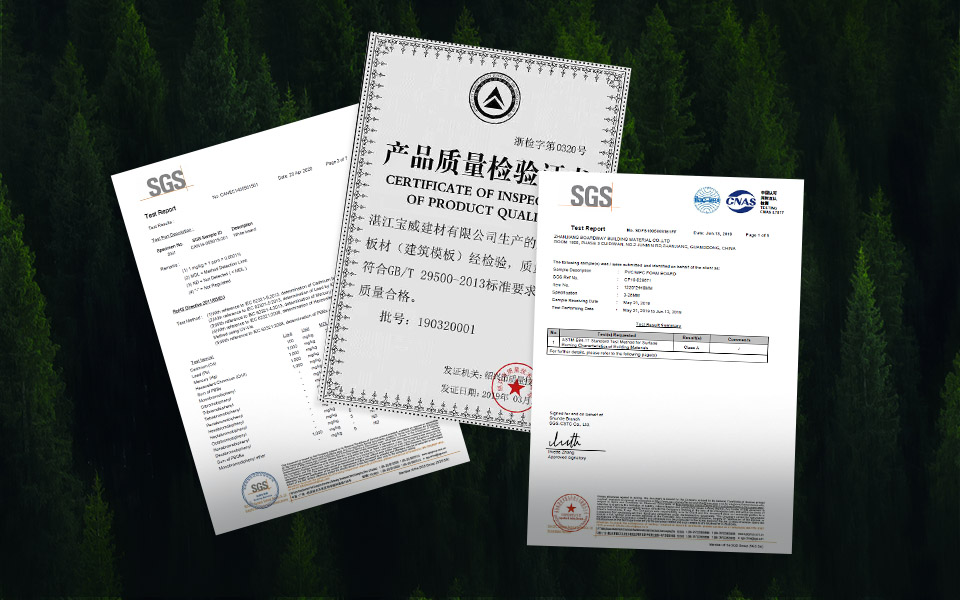

QUALITY CONTROL

Boardway places a strong emphasis on our product quality control system, focusing on three critical quality control points. These include:

● Stringent selection of raw material suppliers and quality inspections during the material procurement process

● Spot checks throughout production

● Comprehensive laboratory testing of finished products

Our commitment to quality starts with raw material testing, which is a vital part of our entire plastic board manufacturing chain. In addition to real-time monitoring by our production department, our quality control department conducts spot checks based on order requirements. For boards with custom performance enhancements, we further test the performance of finished products in our laboratory or SGS laboratory.

INVENTORY MANAGEMENT

At Boardway, we maintain a robust and diversified inventory management system. Our well-stocked inventory is designed to cater to the diverse requirements of our customers.

Whether you have urgent orders or require smaller quantities that may fall below typical production thresholds, our extensive inventory ensures that we can meet your needs effectively.

This commitment to flexibility and preparedness sets us apart as a reliable partner in the industry, ensuring that you receive the products you require, regardless of order size. Our inventory management strategy helps us serve you better and minimize any potential supply chain disruptions.

PACKING & SHIPPING

Proper packaging is the basic guarantee to ensure that the product remains in good condition during shipping and storage. Our commitment to quality extends to every step, including packaging and shipping.

We understand the importance of timely deliveries and ensure that your orders are shipped promptly to prevent any disruptions to your business. As an experienced importer, you can trust us to use secure and efficient packaging methods, minimizing the risk of damage during transit.

We also make sure that customs clearance is streamlined, reducing any unnecessary delays and additional costs. With many years of export experience, Boardway is dedicated to making your job easier and your business more successful.

GET A QUOTE

- Phone

- *Title

- *Content

Manufacturing, Wholesale, Custom Processing for Plastic PVC Sheets and Profiles