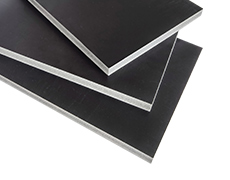

Grey PVC Foam Board

Before sanding

After sanding

Boardway, with over 15 years of expertise in manufacturing extruded plastic sheets, extends its proficiency to offer top-notch processing services for plastic products. Explore our comprehensive processing capabilities categorized into three aspects: cutting and finishing, surface and edge treatment, and printing. Our cutting, finishing, laminating, and edge-sealing services for PVC foam boards are ideal for both indoor and outdoor decoration and furniture applications. If you're a furniture wholesaler or a decoration company, we are delighted to provide OEM services, encompassing plastic sheets and processing. Additionally, our advanced printing services, including silk screen printing and digital printing, cater to diverse customization needs. Have specific needs? Reach out to us—we're here to help!

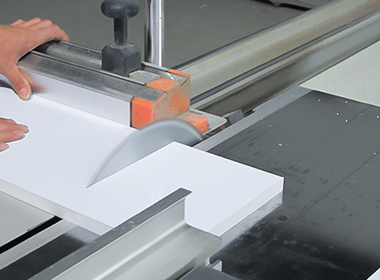

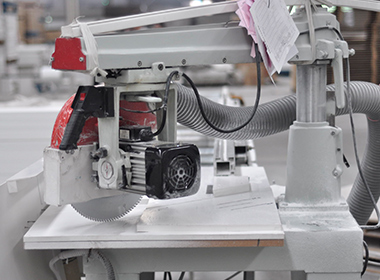

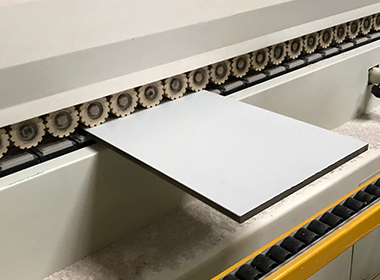

To meet the rectangular cutting needs of plastic sheets, Boardway employs a sliding table saw for small quantities and low-dimensional precision cutting orders. For larger quantities and precise size cutting requirements, our CNC sawing machine ensures uniform size and accuracy. We specialize in plastic sheets cutting, ensuring your specific dimensions are met.

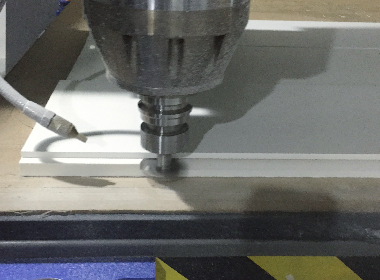

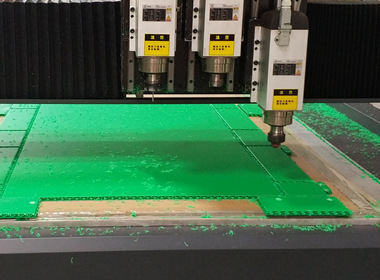

For intricate designs, holes drilling, surface or cross-section grooving, or any CNC engraving needs, Boardway offers three CNC engraving machines with a maximum operating size of 2000mm*3000mm. Our CNC engraving services are ideal for plastic sheets cutting in more complex shapes, ensuring precise and accurate cuts.

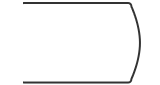

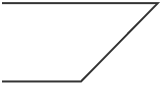

Our finishing services involve chamfering and polishing the edges and corners of boards to create rounded, non-sharp surfaces. Whether it's creating grooved and tongued joints for seamless splicing or performing a 45° beveling treatment for adjacent boards at 90° angles, our expertise extends beyond mere plastic sheets cutting. These finishing techniques are especially beneficial for furniture and decoration.

Straight Edge

Double Round

Double Bevel

Crescent

Full Bullnose

45° Bevelling

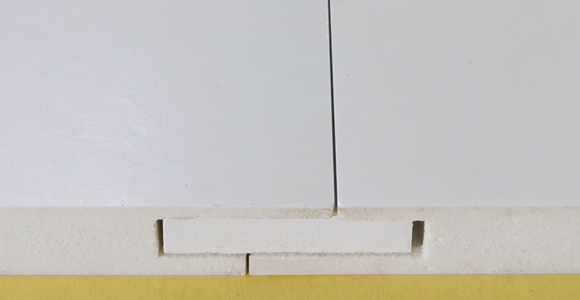

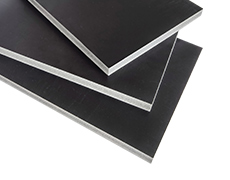

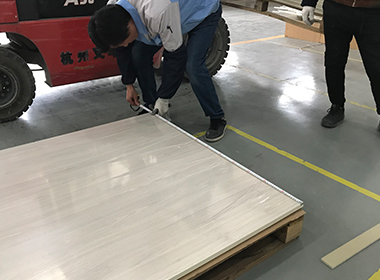

When PVC foam board, wood-plastic composite board (WPC foam board), rigid PVC sheet are used as the base material and surface materials need to be pasted, for example, stick inkjet adhesive to make advertising board, or laminate decorative film to make furniture board or wall panel, surface sanding becomes crucial. We meticulously sand the surface of the board to increase friction, ensuring a robust bond for applications like advertising boards and furniture panels.

Before sanding

After sanding

Before sanding

After sanding

When PVC foam board or WPC foam board serves as a substrate for lamination, PUR laminating is the ideal processing method. PUR adhesives, known for their high water and temperature resistance, prevent remelting, making them suitable for various industrial applications. Our dedicated PUR laminate processing line accommodates materials such as PVC film, PETG film, HPL, aluminum, acrylic, etc. To enhance the adhesion and durability of the surface material, surface sanding precedes lamination.

Our edge banding services encompass straight-line edge banding and contour edge banding. Edge banding not only enhances durability by preventing direct exposure of the core layer but also provides impact resistance, averting edge breakage. Aesthetically, it conceals rough edges, creating a glossy finish that complements both the surface and sides of the board.

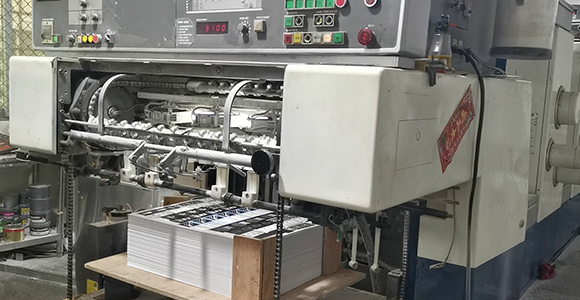

Unlike digital printing, everything is set and processed by a computer. Silk screen printing is more like a purely manual skill. From color adjustment to printing layering, the quality of the printed product depends on the skills of the workers. The reflective effects, hazy effects, glossy and matte effects of the image can all be easily printed by our technicians.

Apply to: image printing without multiple colors and no color gradients.

Advantages: low cost, fast printing speed, good color fastness. The thickness and size of the board are not limited.

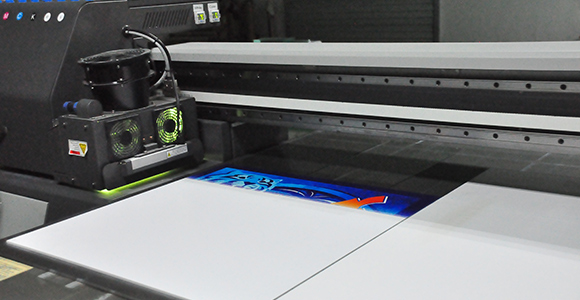

As a professional printing manufacturer, Boardway also provides digital printing services. The types of digital printing we provide are UV printing, CMYK offset printing, inkjet printing. Different printing equipment is suitable for different printing materials, we will provide the best solution according to your printing requirements.

Apply to: image printing with multiple and complex colors, and color gradients.

Advantages: The printing effect is closer to the image, and the MOQ is small.

At Boardway, we specialize in bringing your unique ideas to life. Explore our extensive collection of custom projects and witness the possibilities firsthand. Browse through our customer showcase, featuring a diverse range of customized creations across various industries, including advertising, interior design, furniture manufacturing, and more. Immerse yourself in a visual journey of innovation and inspiration, where each project reflects the collaborative effort between our skilled team and visionary clients.

Click to explore our customer customization gallery and witness the transformative power of our bespoke solutions. Let these captivating examples ignite your imagination and pave the way for your next extraordinary project. Embark on a journey of limitless creativity with Boardway as your trusted customization partner.

Learn More >

Our team will consult with you to understand your requirements and objectives, gathering necessary information for a customized solution.

Based on the consultation, we'll create innovative design concepts aligned with your vision, using sketches, renderings, or 3D models.

Our experts will guide you in selecting suitable materials that meet your aesthetic and functional needs from our high-quality range.

We'll produce prototypes using advanced techniques, rigorously testing them to meet your specifications and standards.

After reviewing prototypes, we'll work closely with you to refine the design until you're satisfied, then proceed to production.

Our skilled craftsmen and state-of-the-art facilities will transform the approved design into the final product with exceptional quality and precision.

We can help you procure necessary components or accessories that complement your customized foam boards.

We maintain rigorous quality control measures throughout the customization process, ensuring durability, performance, and adherence to your specifications.

Our solutions take use, performance, cost and marketing into consideration to find the best fit for your needs.

Manufacturing, Wholesale, Custom Processing for Plastic PVC Sheets and Profiles