Fabrication Techniques Of PVC Foam Boards

Fabrication Techniques Of PVC Foam Boards

According to the production process, PVC foam board can be categorized into:

PVC free foam board is produced by the hot melt extrusion of a flat profile that is subsequently cooled through a three-roller setting machine, edge trimmed, cut to length and palletised. The mould opening is bigger than the product thickness, which let the material can be fully foaming in the mould.

PVC free foam board is not smooth, with a bit of matte finish and good toughness, which can be widely applied to advertising printing, model making etc.

Standard sizes: 1220X2440mm, 1560X3050mm, 2050X3050mm

Thickness: 1-10mm

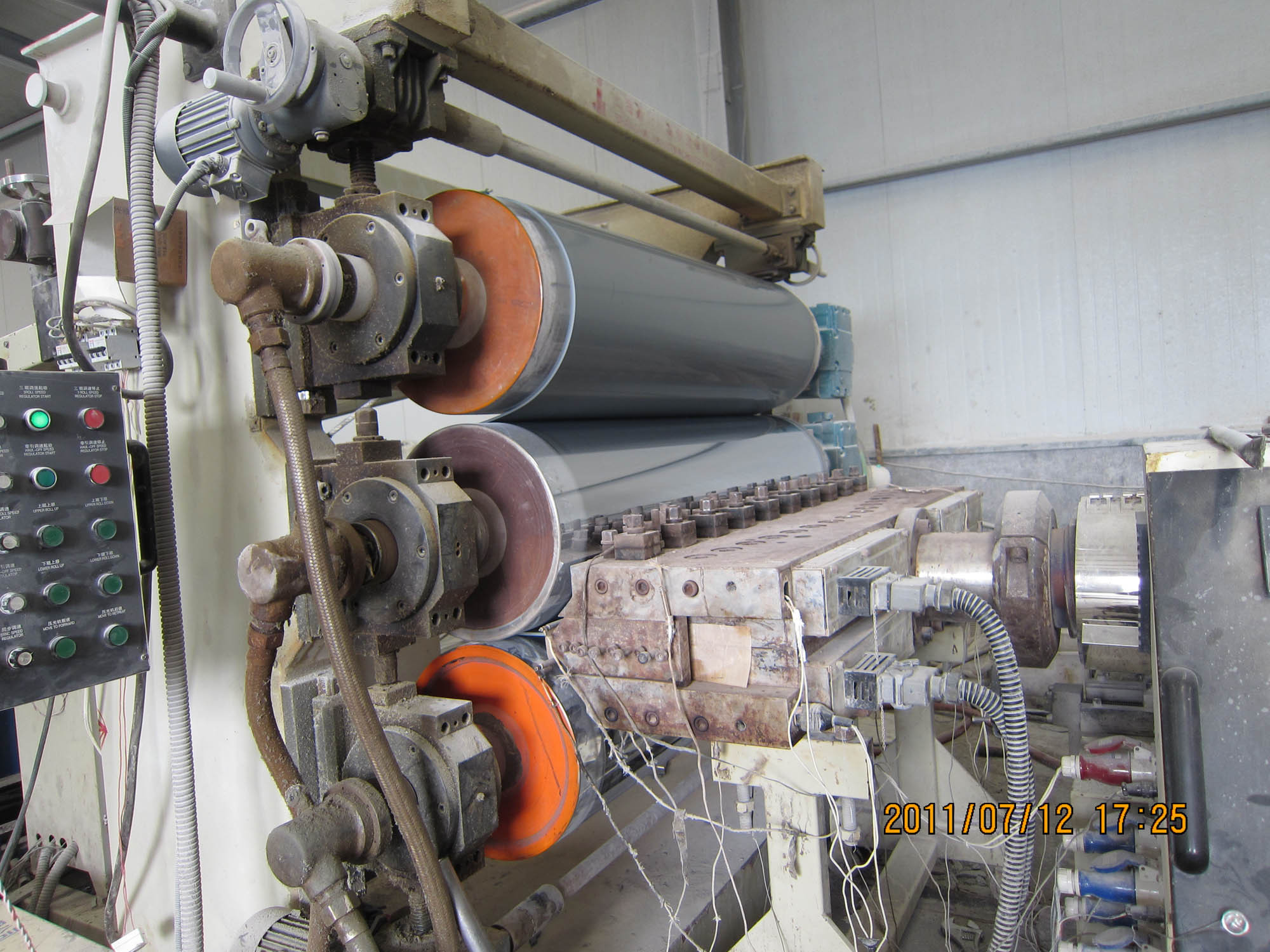

Let's see how PVC free foam boards are produced?

PVC celuka foam board - during the production process, the opening of the mould is small so as to prevent the skin material from fully foaming, and thus forming strong crust on both sides. Therefore, the surface is much harder than that of PVC free foam board, and not easy to cause scratches. Besides, the surface finish is smooth. PVC celuka board can be widely applied to bathroom cabinets, decorations, partition boards, screens, engraving etc.

Common sizes: 1220*2440 mm

Thickness: 3-37mm

Let's see how PVC celuka foam boards are produced?

PVC co-extruded foam board - during the production process, two molds are required to work at the same time. The material from one mold is used for the upper and bottom skins of the co-extruded board, and the material from the other mold is used for the core,So we can see that the upper and bottom skins are thin and not foamed, but the core layer is thick and foamed. Compared with PVC celuka board, the surface of PVC co-extruded foam board is very shiny and super hard.

PVC co-extruded foam board is widely used in advertising and furniture due to its excellent performance on glossy and hard surface. It does not need to be painted, and thus called paint-free boards.

Common sizes: 1220*2440 mm

Thickness: 3-20mm

Let's see how PVC co-extruded foam boards are produced?

GET A QUOTE

Have a great idea but not sure where to start? We’re here to help! Tell us your vision, and our expert team will guide you to the perfect material and solution. Email us at sale@boardwaybuilding.com

- Phone

- *Title

- *Content

Manufacturing, Wholesale, Custom Processing for Plastic PVC Sheets and Profiles