What Are the Common Quality Issues of PVC Foam Board?

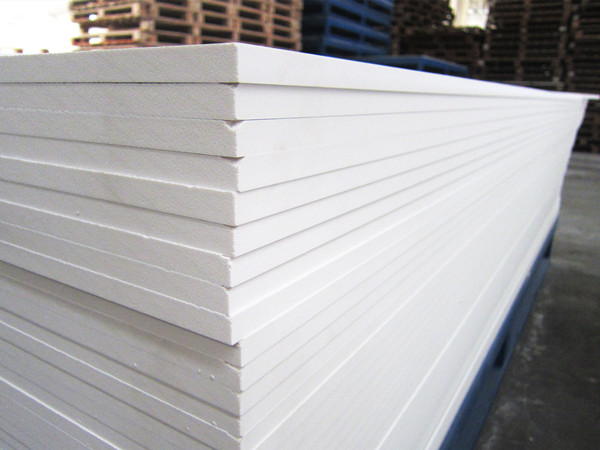

As a rigid expanded PVC sheet, PVC foam board has a uniform closed-cell foam core and hard skin structure, which makes it lighter than solid PVC sheet, while maintaining good flatness and strength.

We often say that PVC foam board is an ideal alternative for traditional wood board. This is because it is superior to wood panels in terms of water resistance, mildew resistance, termite resistance, flame retardancy, corrosion resistance and weather resistance. And as one of the Chinese manufacturers and wholesalers of PVC foam board, we often have customers who are using plywood or MDF board, inquiring that they want to use PVC foam board to replace wood materials, and place a trial order to us.

Since it is the first time to buy or use, how do you know the quality of the PVC foam board provided by the supplier?

This got us thinking, why not write a blog about common quality issues of PVC foam board. Let them, who are purchasing PVC foam board for the first time, correctly identify the quality of the PVC foam board provided by their suppliers. Sometimes, it may not be that the PVC foam board fails to meet your requirements, but that the PVC foam board you get is of poor quality.

· Yellowing of the board surface

You bought a white PVC foam board, but what you received is a yellowish PVC board? This is of course due to the poor quality of the PVC foam board.

· Graying of the foam core

Such quality issue is related to the raw materials used in the production of PVC foam boards. After cutting the PVC foam board, the exposed core is blackish or grayish. This situation shows that the PVC foam board is likely to be produced using inferior raw materials. Such PVC foam sheets have poor physical properties and a short service life.

· Defects on the board

Impurities, dirt and pits on the board surface are due to contamination of raw materials or production lines. High-quality PVC foam board requires a clean and hygienic production workshop.

· Wrong specification

The length, width and thickness are not as requested in the order and are out of tolerance. Thickness tolerances are even more critical if PVC foam panels need to be inserted into slots for assembly. When the thickness of the PVC foam sheet is out of tolerance, the result is that the sheet cannot be inserted into the slot or is too loose in the slot.

· Uneven thickness

A standard size PVC foam board, which is 1220x2440mm. We measure the thickness every 200mm across its width. A total of 7 thicknesses were obtained, and the max. and min. values were compared, which exceeded the tolerance range.

· Damage to the board

Scratched surface are due to poor protection. If the edge of the board is chipped, this is caused by the equipment not being adjusted properly when cutting the board at the end of the PVC foam board production line.

· Large cells

The foamed core exposed on the side of the board should have closed cells of uniform size without large cells. Like the previous quality issue, the large cells are also indicate that the manufacturer's production process is not up to standard.

· Damage caused by poor packaging

Many suppliers do not have extensive export experience and do not realize the importance of packaging to the safety and security of goods. Improper packaging will cause damage such as indentation and cracking of the PVC foam sheet.

Our suggestion

· Get samples before order, trial order before bulk order

Before placing a trial order or bulk order, it is best to get a sample of the PVC foam board from the supplier. Only place an order after you approve the quality and color of the sample. More importantly, after receiving the trial order or bulk product, compare it with the sample you confirmed at the beginning.

Take ourselves as an example, we provide different types of white PVC foam boards to customers in different countries and regions. For example, some customers prefer white PVC foam boards that are a bit more beige, and some customers prefer white PVC foam boards that are as white as paper. The PVC foam board provided by different factories will also have different types of white. So the sample is the most effective way to confirm the color.

· Keep your suppliers fully informed of your requirements

We strongly recommend that when negotiating an order with your supplier, explain your application, performance and specification requirements to them in as much detail as possible to ensure they produce according to your requirements.

However, the skin or core is not hard enough, and the nail holding powder is weak, which is not entirely a quality issue in our opinion. Density is the direct factor that affects them. Increasing the density of the board can effectively improve the hardness and nail holding power. Secondly, we will also adjust the equipment to produce a harder or more flexible PVC foam sheet according to the customer's application and requirements.

Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 years of experience in the manufacture and application of PVC foam board and other plastic sheets. If you would like to know more about PVC foam board, or you have the needs of custom PVC foam board, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale@boardwaybuilding.com.

Boardway Processing Services

1. Cut to size and CNC engraving

2. Silk screen printing, digital printing, painting

3. Thermal processing, bending, embossing

4. Pre-drill, nail, screw and assemble

5. Sanding, PUR lamination, PVC edge banding

6. Corners and edges rounding, chamfering, grooved and tongued