How to Process PVC Foam Board? Share from PVC Sheet Manufacturer

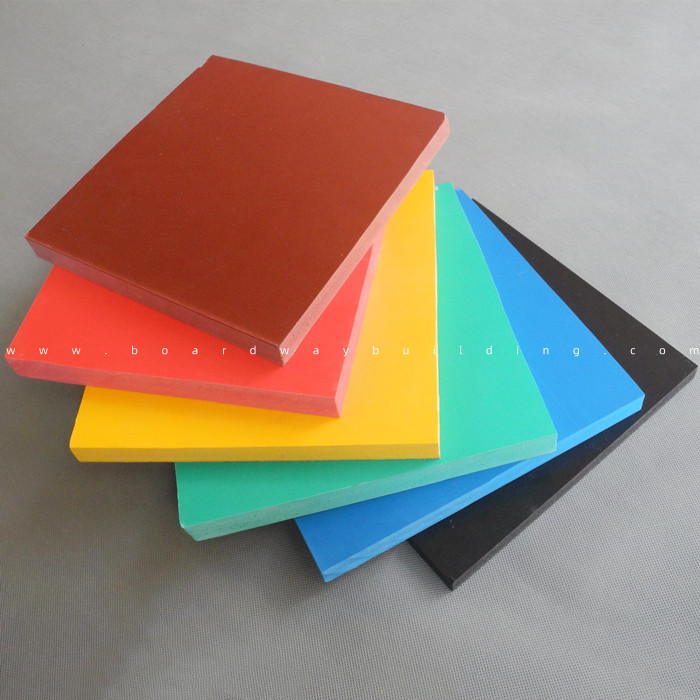

As an ideal alternative to wood panels, PVC foam board has many advantages that wood panels do not have, such as waterproof, mildew-proof, flame-retardant, printable, available in colors, and can have different surface textures. At the same time, the closed-cell and flat structure of expanded PVC sheets also makes it as easy to process and easy to use as wood panels. With common woodworking tools, the processing of PVC foam board can be carried out.

Let's take a look at which processing method is suitable for PVC foam board, so that people who have not used PVC foam board can know whether PVC foam board meets your needs before buying.

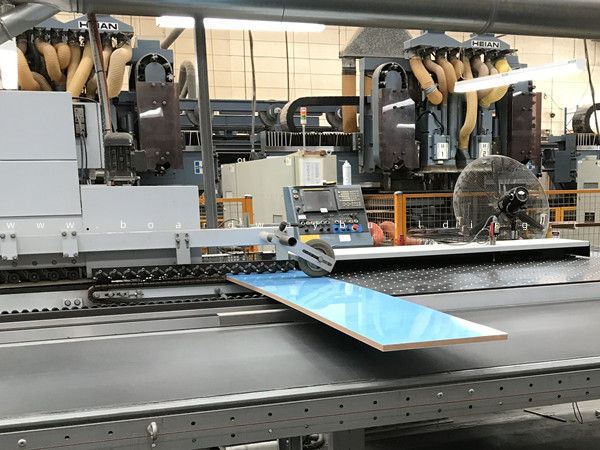

Cut to size and engraving of PVC foam board.

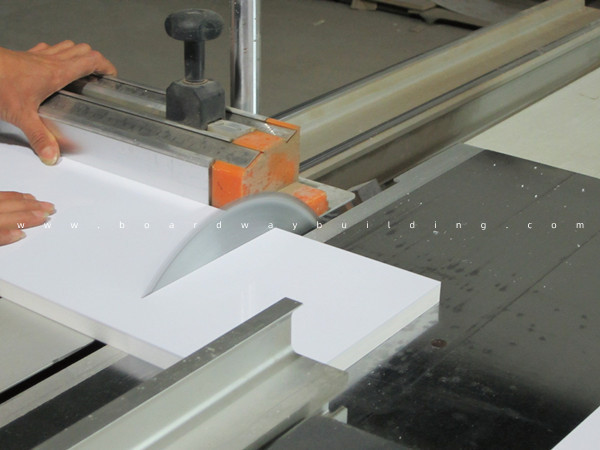

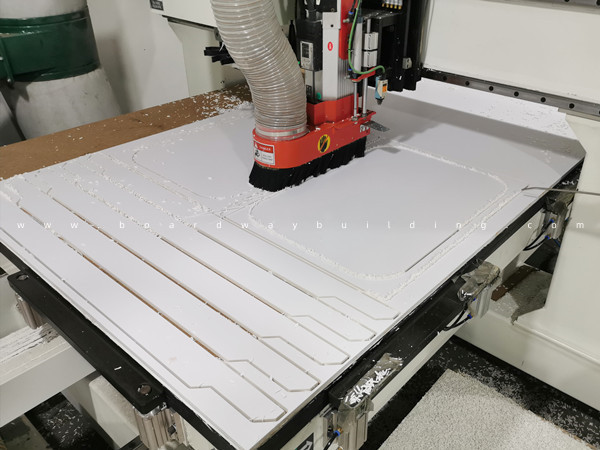

To cut the PVC foam board into small size, the processing method is sawing or CNC cutting.

Both cutting methods can cut the sheet to size, the difference is the dimensional tolerance. When the dimensional accuracy of the PVC foam sheet is not a high requirement, it is more convenient to use the sawing method. However, if the application of PVC foam sheet requires it to have a more precise dimensions, then it must be cut by a CNC cutting machine (CNC router). Of course, different CNC cutting machines and different cutters also have different cutting tolerances.

PVC foam board can be cut into any shape, or it can be engraved into openwork panel. For use as an openwork panel, we would recommend using high density PVC foam board. The expanded PVC board with higher density has finer cells, making the exposed foam core more aesthetically pleasing.

If you have a PVC foam board with a thickness of 1mm or 2mm, it can be cut with a knife. For thicker PVC foam sheets, it may not be possible to cut them all at once with the knife.

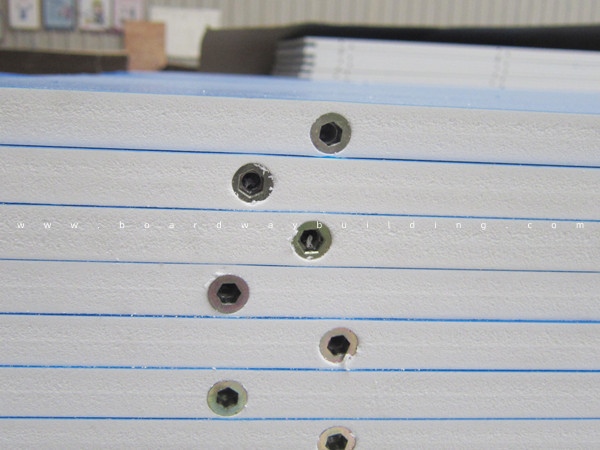

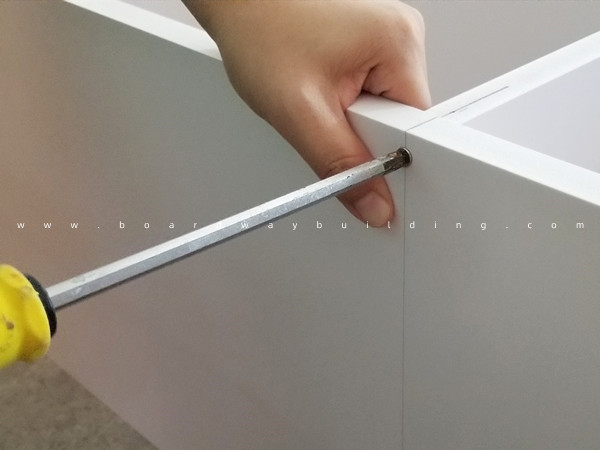

PVC foam board can be drilled, nailed, screwed.

Nails and screws are used to assemble the PVC foam board. The working tools are very simple, such as screwdrivers, electric drills, and gun nails. Customers who use PVC foam board to make furnitures or advertising signs and displays often care about whether our PVC foam board has enough screw holding strength.

How about the screw-holding strength of PVC foam board? let's take a look at the following test video.

If you have not used PVC foam board before, we recommend you to contact us to get a free sample for testing. Then you can personally test and feel whether its screw-holding strength meets your needs before purchasing a full-size board (PVC foam board 4x8).

PVC foam board can be rounded, chamfered and grooved.

When PVC foam board is used as a furniture board, we may want it to be non-sharp and the edges and corners are rounded. In order to facilitate installation, we may also hope that the PVC foam board can be assembled by grooves and tongues.

A 3D CNC engraving machine can complete rounding, chamfering and grooving in one stop. For us, the rounded corners and grooves of the PVC foam board are processed by the CNC engraving machine. Then we use a hand edge-chamfering machine to polish its edges. By replacing different cutters, the radius of edge chamfering can be 2mm, 3mm, 5mm, or we can make custom cutters to customize the type of chamfering.

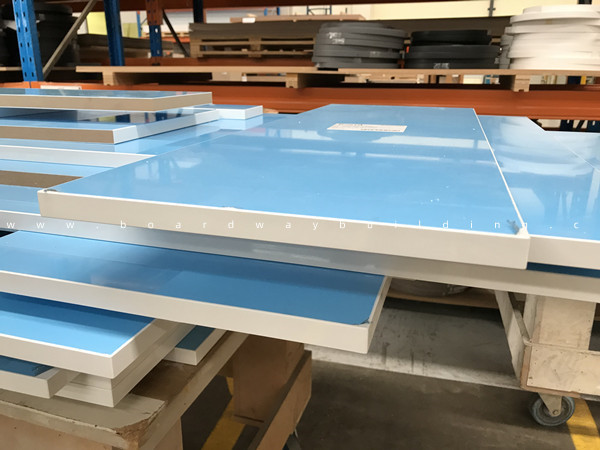

PVC foam board can be sanded, laminated and edge banded.

When white PVC foam board or plain color PVC foam board cannot meet the needs of furniture application, we can laminate it with a decorative surface material. We call it PVC foam board laminate. There are many options for surface material, PVC film, high pressure laminate (HPL), aluminum sheet or aluminum film, acrylic sheet, PET sheet. The PVC foam board with decorative surface material is rich in styles and can meet more decoration styles and application scenarios.

For a tighter lamination performance, we can sand the PVC foam board before lamination. Small areas can be processed with sanding paper by hand. When it is necessary to sand large quantities of PVC foam board with full-size, we process them on the production line.

In addition, PVC foam board can also be processed with edge banding. Its working method is the same way as the wood panel.

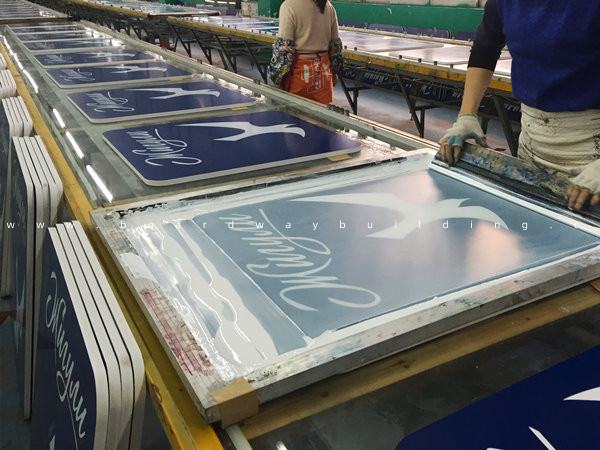

PVC foam board is printable and paintable.

PVC foam board can be printed, and the printing method can be silk screen printing or digital printing. PVC sign board (PVC free foam board) is a printing material that is widely used in the advertising industry. The sign boards made of PVC foam board can be used both indoors and outdoors.

However, it should be noted that the ink of different printer brands may have different printing performance on the PVC foam board, that is, whether the printing is firm and whether the prints is easy to be scratched off. When this happens, we can't say that it is because the ink or the plate is good or bad, but they do not match each other. Therefore, we strongly recommend that customers must take a sample of PVC foam board and print it on your printer before purchasing, and check the printing performance.

PVC foam board can be thermally processed.

The thermal processing of PVC foam board refers to heating the PVC foam board to soften it, put it into a mold and apply high pressure, and make the flat board into an embossed board or a curved board. It is important to note that after the sheet is hot-pressed, be sure to place the sheet horizontally until it cools down completely.

Just like PVC foam board laminates, embossed PVC sheets or curved PVC sheets add more styles and designs to customers than ordinary PVC sheets. The thermally processed PVC foam board still retains its own advantages.

PVC embossed panels are popularly used on the front panels of bathroom cabinets and kitchen cabinets. Curved PVC concrete formwork can be used in cylindrical buildings, cambered buildings and bridge buildings.

Boardway Processing Services

We provide the above mentioned processing methods for PVC foam board.

1. Cut to size and CNC engraving

2. Pre-drill, nail, screw and assemble

3. Corners and edges rounding, chamfering, grooved and tongued

4. Sanding, PUR lamination, PVC edge banding

5. Silk screen printing, digital printing, painting

6. Thermal processing, bending, embossing

Click to view Boardway Product List

Click to view Boardway Processing Services

Click to view Boardway Custom Product Gallery