How Does PVC Foam Board Perform Outdoors?

When it comes to outdoor applications, finding the right material that can withstand the elements while maintaining its performance is crucial. PVC foam board has emerged as a popular choice for outdoor projects, thanks to its exceptional durability, versatility, and weather resistance. Whether you're constructing signage, outdoor furniture, or decorative elements, understanding the performance of PVC foam board in outdoor settings is essential to ensure long-lasting and reliable results.

In this article, we will explore the key factors that make PVC foam board an excellent choice for outdoor use, the importance of using outdoor-grade materials, and practical tips to extend its lifespan. As a leading manufacturer and supplier of PVC foam board, Boardway is committed to providing high-quality products that meet the demands of various outdoor applications. Let's dive into the world of PVC foam board and discover how it excels in outdoor environments.

What is the performance of PVC foam board outdoors?

1. Weather resistance

PVC foam board exhibits good weather resistance, including exposure to sunlight (ultraviolet radiation), rain, temperature fluctuations and humidity. It is designed to withstand the elements without significant degradation.

2. Fading and discoloration

Like many materials, PVC foam board may show some degree of fading or discoloration over time when exposed to sunlight for a long time. However, high-quality PVC foam boards are often manufactured with UV stabilizers that help minimize this effect.

3. Moisture resistance

PVC foam board has inherent moisture resistance, which helps to protect it from damage caused by water absorption, warping or rot. This makes it suitable for outdoor applications that require exposure to rain or moisture.

4. Structural Integrity

PVC foam panels maintain their structural integrity even in outdoor environments. It won't warp, crack or crack easily, making it a reliable choice for outdoor signage, decoration or other applications.

The case of PVC foam board used outdoors

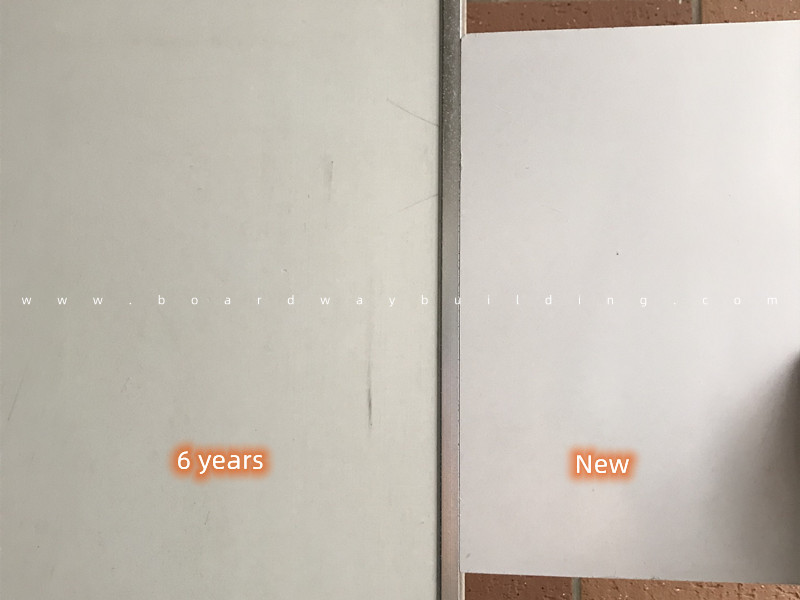

The following pictures show a PVC cabinet (made of standard PVC foam board) placed on the balcony, which is exposed to the sun for about 12 hours a day and has been used for more than 6 years.

However, when we compare it with the new PVC foam board sample, we can intuitively see the color change of the PVC cabinet.

Outdoor-grade PVC foam board

Although PVC foam board can be used outdoors, it is important to consider the specific type and grade of PVC foam board suitable for outdoor use. As far as our factory is concerned, we have PVC foam board specially for outdoor use. Outdoor-grade PVC foam sheets are engineered to withstand the elements, including UV radiation, moisture, and temperature fluctuations. These outdoor boards are generally more resistant to fading, warping and degradation due to weather conditions. When purchasing, you only need to tell us its purpose, use environment and performance requirements.

Is there any way to prolong its life outdoors?

- Proper installation: Ensure that PVC foam boards are properly installed using appropriate fasteners and techniques. This includes providing adequate support and spacing to prevent excessive flexing or bending.

- Protect from extreme conditions: While PVC foam board is designed to withstand various weather conditions, extreme temperature fluctuations or prolonged exposure to harsh sunlight may affect its performance. Consider providing additional shade or protection in areas with intense sunlight or extreme weather conditions.

- Regular cleaning and maintenance: Clean the PVC foam board regularly to remove dirt, dust, and debris that can accumulate over time. Use a mild detergent and a soft cloth or sponge to avoid scratching the surface. Regular maintenance helps preserve its appearance and overall condition.

- Use proper adhesives and sealants: When bonding PVC foam board or attaching it to other surfaces, use adhesives and sealants specifically formulated for PVC materials. This ensures proper adhesion and helps prevent moisture intrusion.

- Avoid excessive bending or stress: While PVC foam board is relatively durable, excessive bending or stress can affect its longevity. Avoid placing heavy objects on unsupported areas or subjecting it to excessive mechanical stress.

It should be noted that the specific performance and longevity of PVC foam board outdoors can vary depending on the quality of the material, the manufacturing process, and the specific environmental conditions. Choosing a high-quality PVC foam board from a reputable manufacturer can provide better performance and longer lifespan in outdoor applications.

Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 years of experience in the manufacture and application of PVC foam board and other plastic sheets. If you would like to know more about PVC foam board, or you have the needs of custom PVC foam board, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale@boardwaybuilding.com.

Boardway Processing Services

1. Cut to size and CNC engraving

2. Silk screen printing, digital printing, painting

3. Thermal processing, bending, embossing

4. Pre-drill, nail, screw and assemble

5. Sanding, PUR lamination, PVC edge banding

6. Corners and edges rounding, chamfering, grooved and tongued

Click here to visit our factory.